Understanding tractor braking system: a comprehensive guide

Introduction

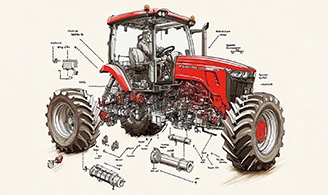

Tractors are powerful machines used primarily in agricultural settings. They are designed to perform a range of tasks, from ploughing fields to hauling heavy loads. One of the most critical components of a tractor is its braking system. Proper understanding and maintenance of the braking system are vital for the safety and efficiency of the tractor's operation.

Types of Braking Systems in Tractors

There are several types of braking systems commonly found in tractors, including:

1. Mechanical brakes

Mechanical brakes utilize physical force to create friction and stop the tractor. These are typically found in older models and are known for their simplicity and reliability. The main components include brake drums, shoes, and linkages.

2. Hydraulic brakes

Hydraulic brakes are more advanced and are commonly used in modern tractors. They work by using fluid pressure to force the brake pads against the rotors, creating the necessary friction to stop the tractor. Key components of hydraulic brakes include master cylinders, brake lines, calipers, and brake pads.

3. Air (pneumatic) brakes

Air brakes are often found in larger tractors and heavy equipment. They use compressed air to activate the brake mechanism. This type of braking system is known for its efficiency and ability to handle heavy loads. Components include air compressor, air lines, brake chambers, and slack adjusters.

Components of tractor braking systems

Understanding the components of tractor braking systems is essential for proper maintenance:

1. Brake pedal

The brake pedal is the user interface for engaging the braking system. It translates the operator's force into the mechanical or hydraulic action needed to slow down or stop the tractor.

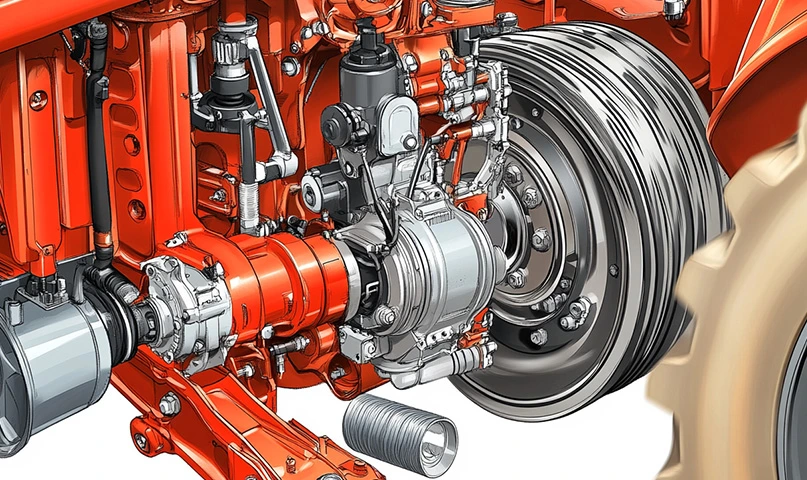

2. Brake drums and discs

Brake drums and discs are the surfaces against which the brake pads or shoes press to create friction. Drums are typically used in mechanical brake systems, while discs are found in hydraulic systems.

3. Brake pads and shoes

Brake pads (used in disc brakes) and shoes (used in drum brakes) are the components that directly contact the braking surface to create friction. These must be regularly inspected and replaced as they wear down.

4. Master cylinder

In hydraulic brake systems, the master cylinder is the component that converts the force of the brake pedal into hydraulic pressure. It is crucial for the proper functioning of the system.

5. Brake lines

Brake lines are the conduits through which hydraulic fluid travels from the master cylinder to the brake calipers. They must be checked for leaks and damage regularly.

6. Calipers

Calipers are part of the hydraulic braking system and hold the brake pads. They apply pressure to the brake discs to create the necessary friction for stopping the tractor.

7. Air compressor

In air brake systems, the air compressor generates the compressed air needed to activate the brakes. It is a vital component for ensuring the efficiency of the braking system.

Also Read https://www.mahindratractor.com/blog/how-tractor-cooling-system-works

Working of a tractor's braking system

Here's a simplified explanation of how the braking system works :

Operator action : The operator presses the brake pedal, which sends force to the master cylinder (hydraulic or pneumatic).

Force transmission : In hydraulic systems, the pressure from the master cylinder pushes the brake fluid through the brake lines to the brake calipers or drums. In pneumatic systems, air pressure is sent through airlines to the brake chambers.

Friction creation : The hydraulic or pneumatic pressure activates the brake pads or shoes, which press against the brake drums or discs. This creates friction, which slows down or stops the tractor's wheels.

Vehicle stoppage : The friction between the brake components and the wheels reduces the tractor's speed and brings it to a stop.

Maintenance tips for tractor braking systems

Proper maintenance of tractor braking systems is crucial for safety and performance. Here are some essential tips:

- Inspect regularly: Conduct regular inspections of all braking components, including brake pads, discs, drums, and lines. Look for signs of wear and tear, and replace any damaged parts promptly.

- Check fluid levels: For hydraulic brake systems, ensure that the brake fluid levels are adequate. Low fluid levels can lead to reduced braking efficiency.

- Conduct air-checks: In air brake systems, routinely check the air compressor and air lines for leaks. Proper air pressure is essential for the system's functionality.

- Maintain cleanliness: Keep the braking components clean and free of debris. Dirt and grime can affect the performance of the braking system.

- Ensure professional servicing: Schedule regular servicing with a professional mechanic who has experience with tractor braking systems. Professional maintenance can help identify and address issues before they become serious.

Conclusion

The braking system of a tractor is a critical component that ensures the safety and efficiency of its operation. Understanding the different types of braking systems, their components, and proper maintenance practices can help tractor operators maintain their equipment in optimal condition. By following the maintenance tips outlined in this guide, operators can ensure that their tractor's braking system remains reliable and effective, contributing to the overall productivity and safety of their agricultural activities.